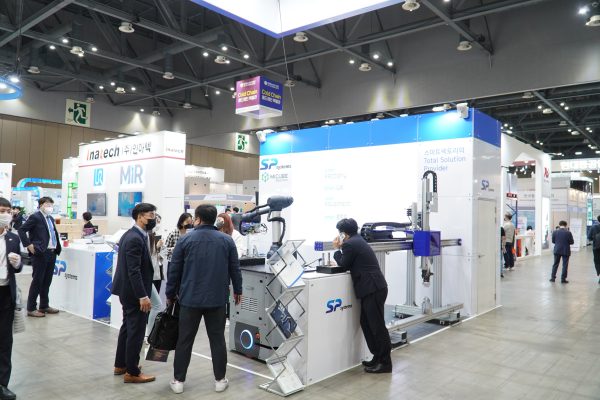

SP Systems participated in the KOREA MAT2021& ICPI WEEK 2021 held at KINTEX, Goyang from May 25 (Tue) to 28 (Fri),and introduced its smart factory total solution for logistics and manufacturingadvancement.

SP Systems focuses on supplying hardwaresuch as logistics automation systems, industrial gantry robots, and cooperativerobots. This time, it formed a joint booth with Micube Solution (CEO ParkMun-won, Shim Hyo-jun), the company that signed a strategic investment contractat this exhibition. This year, it unveiled a diverse lineup that provideshardware, solutions, and AI platforms needed for logistics automation andmanufacturing intelligence.

Especially in this exhibition, the companyintroduced a collaborative robot equipped with an autonomous mobile robot (AMR)as a hardware product of the smart factory total solution lineup. It is anautomated robot that can perform precision work for production and transfer,and with a high-performance 6-axis torque sensor, it can perform sophisticatedtasks like a human arm. It boasts the highest level of stability through thehighest level of collision sensitivity. In addition, a demonstration of thegantry robotics system that can be widely applied to automobile, display,construction, shipbuilding and secondary battery manufacturing processes wasalso held.

Micube Solution's smart factory solutionand AI platform play the role of upgrading the logistics and manufacturingprocess from an overall perspective. Its SmartFactory and SmartEES can trackand manage the status of logistics, production, and equipment from orderreceipt to delivery. The manufacturing-specific AI platform helps to advancefactory operations by providing functions such as predictive maintenance andsearch for optimal process conditions based on the data.

Also, IoT solution that stores, analyzes,and shares various facilities and sensor data in real time through the smartfactory with remote maintenance feature SP RAS (Remote Access Service) was alsoexhibited.

Lim Seok-ho, Deputy General Manager of SPSystems who attended the exhibition, said, "Our main product the gantry,is directly processed and used with core parts. Above all, in the case ofhigh-speed gantry products that can move up to 3M, we are designing them tofunction from a load of 300kg to a maximum of 1t.”

About the main target market, he said,"SP System’s gantry is used in all fields of aviation, shipbuilding, andconstruction and automobiles. It is especially popular in the automotivesector.”

Regarding the performance of participatingin the exhibition, he said, "We are able to provide practical help tocustomers who are thinking about upgrading their factories by introducingcustomized lineups from automation systems to smart factory solutions andactual implementation cases according to customer needs.”

Before the opening of KOREA PACK 2021, anonline exhibition hall service where visitors can see exhibitors’ products wasunveiled on May 17 (Mon). This online exhibition hall was designed for overseasbuyers who cannot enter Korea due to COVID pandemic and Korean SMEs havingdifficulty entering overseas. The organizer is supporting export channels byholding the first online export consultation at the KINTEX from May 25 to 28for Korean exhibitors and buyers that have been matched.

Hosted by Kyongyon Exhibition Co., KoreaPackaging Machinery Association, KIP, and PackNet, the items exhibited at KOREAPACK Special and ICPI WEEK 2021 are as follows. △Packaging machine △Packagingmaterial △Packaging label/digital printing △Packaging robot△Pharmaceutical/cosmetic related machinery △Food related machinery △Packagedesign △Packaging plant engineering system

→ Go to 2021 KOREA PACK Special & ICPI WEEK news special page

→ Go to 2021 KOREA PACK & ICPI WEEK Online Exhibition Hall

KOREA PACK Special & ICPI WEEK 2021 Site Sketch | Filmed by AVING News